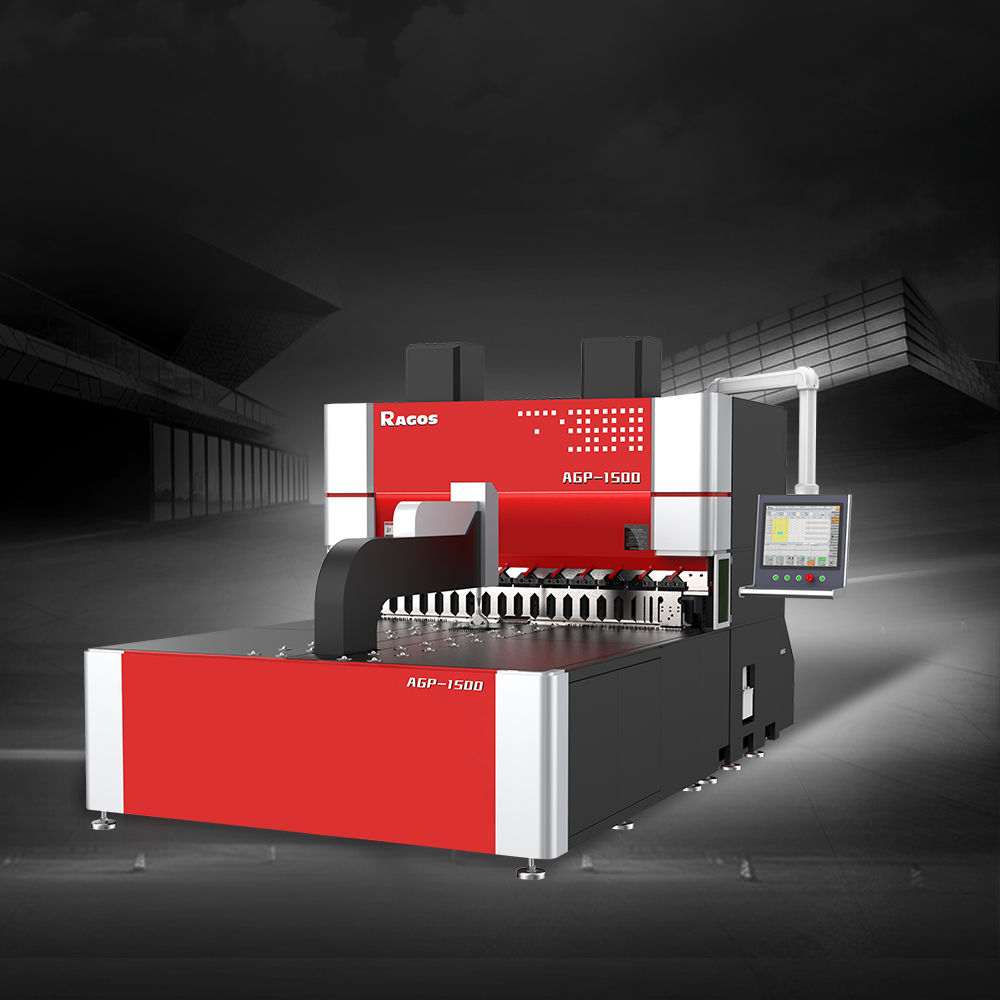

AGP-1500 Panel Bender

The AGP-1500 is a versatile panel bender that combines power and precision for medium to large-scale metal forming operations.

Key Features

- Efficient automatic bending

- Durable cast body

- Energy-saving nitrogen counterbalance

- Maximum bending length of 1500mm

Detailed Description

The Ragos AGP-1500 Panel Bender represents a new pinnacle in bending technology, designed to meet the stringent demands of modern manufacturing for high efficiency, precision, and advanced automation. As an advanced bending machine, the AGP-1500 offers an ideal solution for various metal processing companies with its multiple innovative technologies and exceptional performance. It not only improves production efficiency but also ensures processing accuracy and equipment reliability, making it the best choice for companies pursuing efficient production and high-quality output. The AGP-1500 is particularly suitable for processing heavy, high-density, or large-sized workpieces, meeting the needs for complex shapes and high-precision processing.

Key features and advantages:

1. High-speed, high-precision production: The AGP-1500 adopts a press arm-based bending center design, doubling the bending speed compared to traditional models, significantly enhancing production efficiency. The high-precision servo motor combined with ball screw drive achieves processing speeds of up to 200mm/s while maintaining a positioning accuracy of ±0.01mm. This design ensures high efficiency and precision at every stage of processing, significantly reducing error rates and improving overall product quality. For manufacturing companies with high production demands, this means the ability to process more workpieces in the same time, effectively reducing production costs and increasing market competitiveness.

2. Multi-axis precision control and press arm design: The AGP-1500 comes standard with 13 control axes, with custom models reaching up to 14 axes, far exceeding similar products. This multi-axis precision control system ensures precise processing of complex workpieces and high repeatability, meeting customers' needs for complex shapes and high-precision processing. The press arm design is a key feature of the AGP-1500, especially suitable for processing heavy, high-density, or large-sized workpieces. This design not only improves the dimensional accuracy of the formed workpieces but also enhances processing quality. For workpieces requiring high bending strength, this equipment provides stable and reliable processing results. Whether processing small precision parts or large complex structures, the AGP-1500 can handle the task.

3. Environmentally friendly energy-saving and fully automated production: The AGP-1500 is equipped with an innovative nitrogen counterbalance system that effectively saves energy. Additionally, it uses an independent cooling system, further optimizing the heat dissipation of the equipment, reducing long-term energy consumption and maintenance costs. This environmentally friendly, energy-saving design not only aligns with green manufacturing principles but also helps companies save on long-term operational costs. The AGP-1500 offers an optional automatic loading and unloading system, making 24-hour uninterrupted unmanned production possible. By reducing manual intervention, this equipment lowers labor costs while increasing production efficiency and safety. For mass production enterprises, this is an excellent choice for increasing capacity and reducing costs.

4. High-rigidity structure and ease of use: The body of the AGP-1500 adopts a stable triangular link structure design, ensuring the stability and durability of the equipment during high-speed operation and heavy loads. This high-rigidity body structure effectively reduces vibration and displacement during processing, ensuring the processing accuracy of each workpiece. The user-friendly interface and simplified maintenance procedures are another major advantage of the AGP-1500. The user-friendly interface allows operators to easily master the use of the equipment, while the simplified maintenance procedures significantly reduce operational difficulty and maintenance time, thus increasing overall equipment utilization. These designs not only improve the stability and durability of the equipment but also significantly extend the work cycle, reducing maintenance needs and downtime.

5. Customized configuration and comprehensive technical support: The AGP-1500 can be configured according to specific customer needs, including additional axes and functions to meet specific production requirements. Whether for special-shaped workpieces or complex bending processes, the AGP-1500 can provide optimal solutions for customers through customization. In terms of after-sales service, Ragos offers professional technical consultations and fast-response after-sales service, ensuring that customers receive timely and effective support during equipment use. From equipment installation and adjustment to daily maintenance, Ragos' technical team is always ready to support customers, ensuring the equipment operates in optimal condition and helping customers maximize the productivity of their equipment. This comprehensive support system ensures that the AGP-1500 maintains optimal performance throughout its lifecycle, creating continuous value for users.