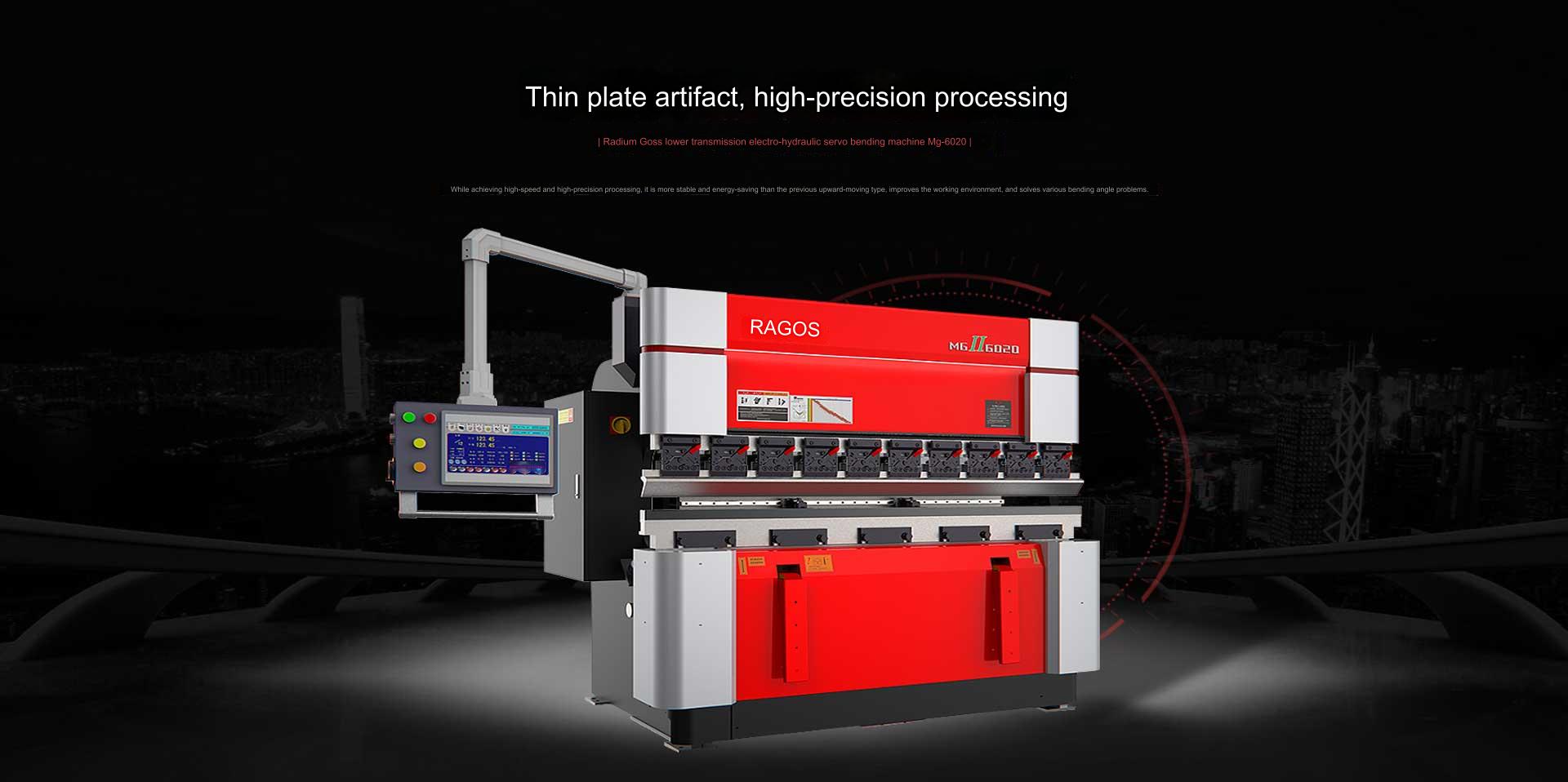

MG-6020 Up-acting Press Brake

RAGOS MG6020 series Up acting hybrid CNC press brake has a nominal force of 60 tons and a workbench length of 2000mm.

Key Features

- High Precision: Accuracy of ±0.05mm

- High Efficiency: 3x more efficient than conventional systems; up to 25 bends per minute

- High Standards: Complies with national and industry standards; advanced R&D and production

- First-Class Craftsmanship: Stable in variable environments with top-tier design

Detailed Description

The RAGOS MG6020 series Up acting hybrid CNC press brake represents a cutting-edge solution for modern manufacturing needs. Offering a nominal force of 60 tons and a workbench length of 2000mm, this machine is engineered to provide high precision, efficiency, and reliability, making it an essential tool for industries demanding consistent and high-quality bending operations.

Key Features and Advantages:

1. High Precision: The MG6020 series delivers exceptional accuracy with precision up to ±0.05mm. This high level of precision ensures that every bend is executed to exact specifications, which is crucial for industries where accuracy is paramount. Whether handling intricate geometries or simple bends, the MG6020 ensures consistent, superior results every time.

2. Enhanced Efficiency: The MG6020 is designed for optimal efficiency, operating at three times the rate of conventional upper-drive systems. With a maximum bending speed of 25 times per minute, this machine significantly reduces production times while increasing overall output, allowing manufacturers to meet tight deadlines without sacrificing quality.

3. High Standards and Craftsmanship: The MG6020 is built to the highest national and mechanical industry standards, incorporating mature R&D technology and a robust production structure. This ensures not only compliance with stringent quality and safety standards but also long-term reliability in various operating conditions. The refined design and high-quality construction contribute to the machine's durability, making it a stable and valuable asset in any production environment.

4. High Positioning Accuracy and Durability: Utilizing high-precision ball screws from Shangyin, the MG6020 offers superior positioning accuracy. Combined with a fully functional backstop, this allows for faster and more precise bending processes. The machine also features high-quality hydraulic cylinders sourced from the original AMADA supplier, forged from 45# steel for exceptional rigidity and strength. These cylinders undergo rigorous testing and annealing to eliminate internal stresses, ensuring stability and reliability over the machine's long service life.

5. Advanced CNC System: The MG6020 is equipped with an advanced CNC system co-developed with Japan's NADIC Corporation. This system includes electro-hydraulic proportional control for both pressure and flow, ensuring high synchronization accuracy between the left and right cylinders. The result is a smooth, stable operation that delivers consistent results across a wide range of applications. The hydraulic piping system, featuring EMB compression fittings from Germany and seamless steel pipes from Japan's Chuo or Parker, ensures a leak-free and clean hydraulic system, enhancing the machine's overall reliability.