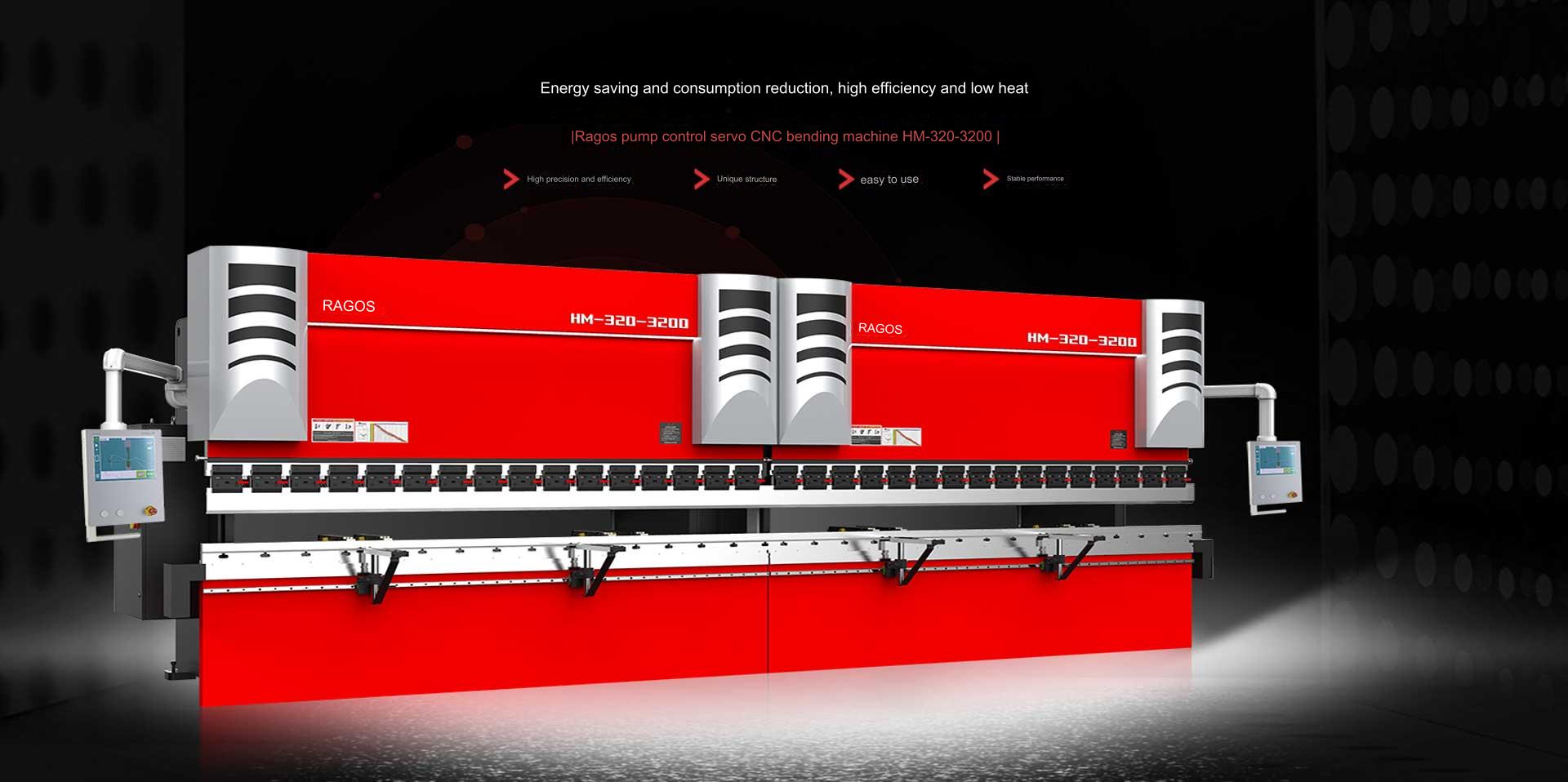

HM-320 Dual Servo Press Brake

The HM-320 series dual servo motor CNC press brake delivers 320 tons of precision bending power, advanced CNC control, and versatile processing capabilities, making it ideal for demanding industrial applications.

Key Features

- Energy saving and consumption reduction

- low noise

- fast speed

- high precision

Technical Specifications

| Model | Nominal force(ton) | Length of workbench (mm) | Distance between columns(mm) | Throat depth(mm) | Slider stroke (mm) | Opening height (mm) | Main motor power(kw) | Speed(mm/s) | Outline dimension(mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fast forward | Working feed | Return | L | W | H | ||||||||

| HM-320-3200 | 320 | 3200 | 2700 | 400 | 300 | 600 | 11.5*2 | 140 | 10 | 120 | 3450+405 | 2400 | 3215 |

| HM-320-4100 | 300 | 4100 | 3500 | 400 | 300 | 600 | 11.5*2 | 140 | 10 | 120 | 4250+405 | 2400 | 3265 |

| HM-320-5100 | 300 | 5100 | 4100 | 400 | 300 | 600 | 11.5*2 | 140 | 10 | 120 | 5060+390 | 2450 | 3565 |

| HM-320-6100 | 300 | 6100 | 5000 | 450 | 300 | 600 | 11.5*2 | 140 | 10 | 120 | 5980+430 | 2470 | 3800 |

HM-320-3200

Nominal force: 320 ton

Length of workbench: 3200 mm

Distance between columns: 2700 mm

Throat depth: 400 mm

Slider stroke: 300 mm

Opening height: 600 mm

Main motor power: 11.5*2 kw

Speed: Fast forward 140 mm/s, Working feed 10 mm/s, Return 120 mm/s

Outline dimension: L 3450+405 mm, W 2400 mm, H 3215 mm

HM-320-4100

Nominal force: 300 ton

Length of workbench: 4100 mm

Distance between columns: 3500 mm

Throat depth: 400 mm

Slider stroke: 300 mm

Opening height: 600 mm

Main motor power: 11.5*2 kw

Speed: Fast forward 140 mm/s, Working feed 10 mm/s, Return 120 mm/s

Outline dimension: L 4250+405 mm, W 2400 mm, H 3265 mm

HM-320-5100

Nominal force: 300 ton

Length of workbench: 5100 mm

Distance between columns: 4100 mm

Throat depth: 400 mm

Slider stroke: 300 mm

Opening height: 600 mm

Main motor power: 11.5*2 kw

Speed: Fast forward 140 mm/s, Working feed 10 mm/s, Return 120 mm/s

Outline dimension: L 5060+390 mm, W 2450 mm, H 3565 mm

HM-320-6100

Nominal force: 300 ton

Length of workbench: 6100 mm

Distance between columns: 5000 mm

Throat depth: 450 mm

Slider stroke: 300 mm

Opening height: 600 mm

Main motor power: 11.5*2 kw

Speed: Fast forward 140 mm/s, Working feed 10 mm/s, Return 120 mm/s

Outline dimension: L 5980+430 mm, W 2470 mm, H 3800 mm

Detailed Description

The HM-320 series dual servo motor CNC press brake is a cutting-edge machine designed for precision bending, high efficiency, and long-term stability in metal processing. Built to meet the needs of industries such as aerospace, automotive, construction, and heavy machinery, this press brake offers versatile and robust performance. A key feature of the HM-320 series is its dual servo motor-driven hydraulic system, which ensures high precision, speed, and repeatability throughout the bending process. With a powerful 320-ton nominal force, this system maximizes production efficiency and ensures consistent product quality, making it ideal for industries where accuracy and reliability are critical.

Key Features and Advantages:

1. Dual Servo Motor Drive System: The HM-320 series is equipped with a dual servo motor-driven hydraulic system that delivers exceptional precision, speed, and efficiency. This system ensures accurate positioning and repeatability, making it ideal for high-volume production environments where consistency is key. The 11 kW*2 motors provide ample power for handling heavy-duty operations while maintaining smooth and efficient performance.

2. Advanced CNC Control System: The HM-320 series features a sophisticated CNC control system with a user-friendly interface that allows operators to set a wide range of processing parameters with ease. The system supports automatic programming, reducing the need for manual adjustments and minimizing the risk of human error. Additionally, the CNC system includes self-diagnostic tools that enable quick identification and troubleshooting of any potential issues, ensuring maximum uptime and operational efficiency.

3. High-Precision Mechanical Design: The HM-320 series boasts a robust mechanical design with a dual-cylinder synchronous transmission system that ensures processing accuracy and stability even at high speeds. The hydraulic system is optimized for efficiency, offering reduced energy consumption and low noise levels. High-performance hydraulic valves further ensure stable and reliable operation, making the HM-320 series suitable for demanding industrial applications.

4. Versatile Processing Capabilities: The HM-320 series is designed to handle a wide range of parts, with table lengths from 3200mm to 6000mm and a consistent nominal force of 320 tons. This versatility allows it to process various materials with precision, making it suitable for a range of industries from sheet metal work to heavy-duty industrial applications. Its adaptability ensures that the machine can meet the specific production needs of different sectors.

5. Ease of Maintenance and Longevity: The HM-320 series is designed for long-term durability and easy maintenance, incorporating high-quality hydraulic and electrical components to ensure stable performance and reduced downtime. The robust construction of the machine minimizes wear and tear, reducing maintenance requirements and extending the operational lifespan. This durability makes the HM-320 series a cost-effective investment, offering reliable performance over many years.