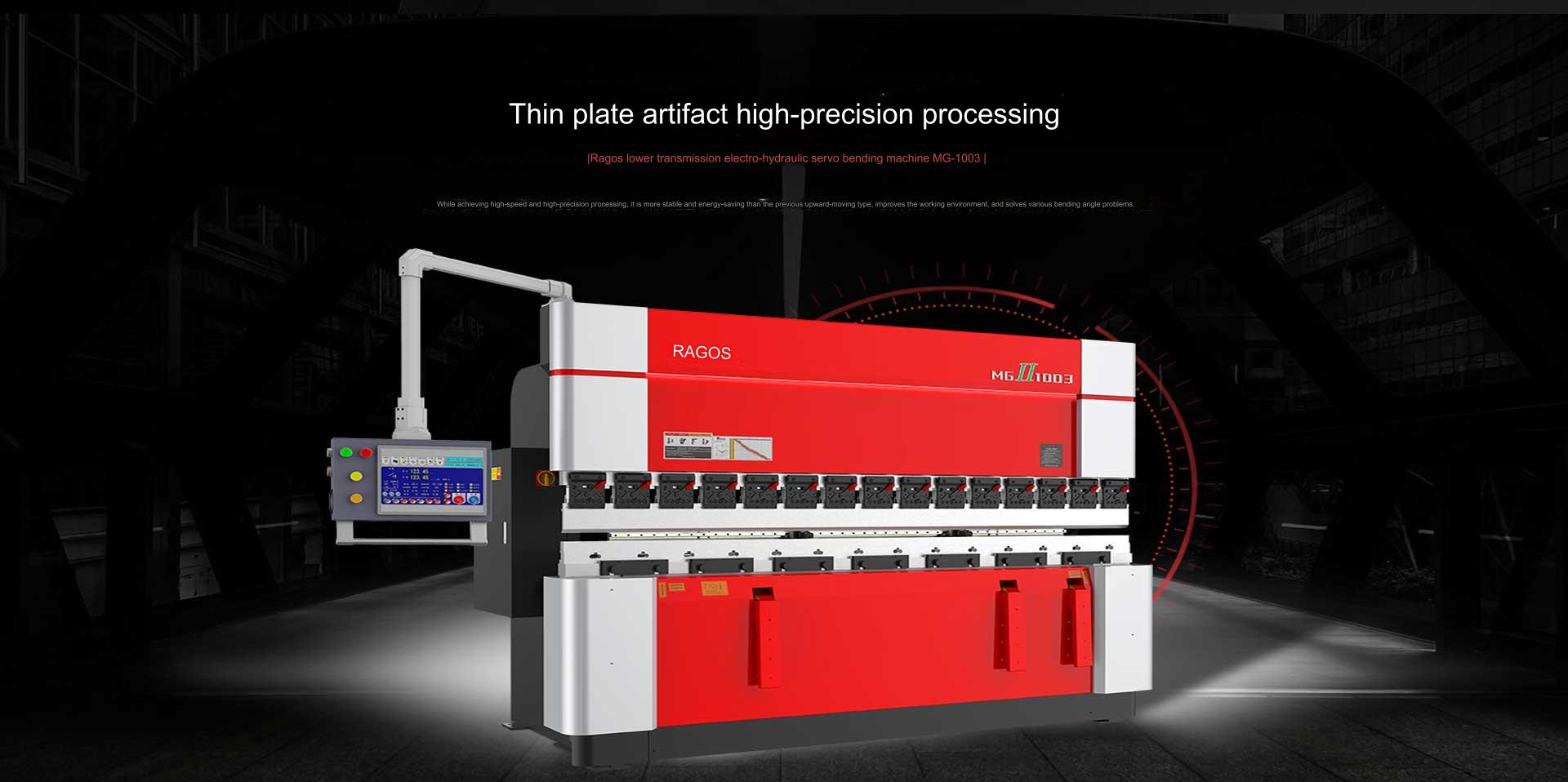

MG-1003 Up-acting Press Brake

RAGOS MG1003 series Up acting hybrid CNC press brake has a nominal force of 100 tons and a workbench length of 3000mm.

Key Features

- High Precision: Accuracy of ±0.05mm

- High Efficiency: 3x more efficient than conventional systems; up to 25 bends per minute

- High Standards: Complies with national and industry standards; advanced R&D and production

- First-Class Craftsmanship: Stable in variable environments with top-tier design

Detailed Description

The RAGOS MG-1003 Hybrid CNC Press Brake redefines precision and efficiency in modern sheet metal processing. It combines cutting-edge technology, user-friendly design, and robust construction, making it a top choice for demanding manufacturing environments.

Key Features and Advantages:

1. Unmatched Precision: The MG-1003 series offers exceptional accuracy, with precision up to ±0.05mm. This ensures that every bend meets stringent quality standards, making it ideal for high-precision applications.

2. Superior Efficiency: Operating at three times the efficiency of conventional systems, the MG-1003 achieves a maximum bending speed of 25 times per minute. This high efficiency reduces production cycles and increases throughput.

3. High Positioning Accuracy: The MG-1003 uses high-precision ball screws and a fully functional backstop to enhance positioning accuracy and speed. This results in faster, more accurate bending processes.

4. Premium Hydraulic Cylinders: The hydraulic cylinders are sourced from the original AMADA supplier, forged from 45# steel for exceptional rigidity and strength. They undergo rigorous testing and annealing to ensure material stability and reliability.

5. Advanced CNC System: Developed in collaboration with Japan's NADIC Corporation, the MG-1003's CNC system offers electro-hydraulic proportional control, ensuring synchronized, stable, and smooth operation across all components.